- Basic Concept of Double-Sided Tape

Industrial double-sided tape is a type of adhesive tape that has adhesive on both sides, widely used across various industries such as manufacturing, assembly, maintenance, and packaging. Unlike traditional single-sided tape, double-sided tape is designed to provide strong adhesion between two surfaces on both sides, making it highly effective, convenient, and non-intrusive. This feature makes double-sided tape essential for bonding, connecting, sealing, and shockproofing in many applications.

One of the core advantages of double-sided tape is its ability to bond two objects together securely without requiring additional tools, such as screws, nails, or welding. As a result, it plays an irreplaceable role in industries such as automotive manufacturing, electronics assembly, building decoration, and furniture installation.

- Basic Structure of Double-Sided Tape

Double-sided tape typically consists of three components: the substrate, adhesive layer, and release liner (or release film).

- Substrate: The substrate is the core material that serves as the base for the adhesive layers. The choice of substrate material greatly affects the tape’s performance, including its adhesive strength, temperature resistance, UV resistance, and flexibility. Substrates can be made from a variety of materials, such as nonwoven fabric, foam, PET film, and more.

- Adhesive Layer: The adhesive layer is the key element that provides bonding power. Common adhesives include acrylic, rubber, and synthetic resins, each with distinct properties. The choice of adhesive type directly influences the tape’s performance in terms of durability, temperature tolerance, and ease of removal.

- Release Liner (or Release Film): The release liner is a protective layer that covers the adhesive side of the tape before it is used. Typically made from paper or plastic with a silicone coating, the release liner prevents the adhesive from sticking to surfaces prematurely, allowing the tape to be stored and used without contamination.

- Common Types of Industrial Double-Sided Tape

Double-sided tape comes in various types, each with different substrates and adhesive systems, designed to meet specific industrial needs. Below are some of the most commonly used types:

- Nonwoven Fabric Double-Sided Tape

Nonwoven fabric double-sided tape uses nonwoven fabric as the substrate, offering excellent flexibility and tear resistance. This type of tape is often used in applications where stretchability and strength are important. It is widely used in industries such as electronics, automotive parts, and signage installation.

Advantages:

- High flexibility and good tear resistance

- Suitable for bonding curved or uneven surfaces

- Excellent temperature and humidity resistance

Applications:

- Electronics assembly

- Automotive interior bonding

- Advertising and signage mounting

- Foam Double-Sided Tape

Foam double-sided tape is made from foam materials, such as polyurethane or polyethylene foam. This type of tape not only offers strong adhesion but also provides cushioning and sealing properties. The foam’s elasticity and thickness make it ideal for applications that require vibration dampening or filling gaps.

Advantages:

- Excellent shock absorption and vibration damping

- Good sealing properties, ideal for waterproofing and dustproofing

- Provides long-lasting adhesion

Applications:

- Automotive parts fixation and sound insulation

- Electronics protection and shockproofing

- Sealing and fixation in construction

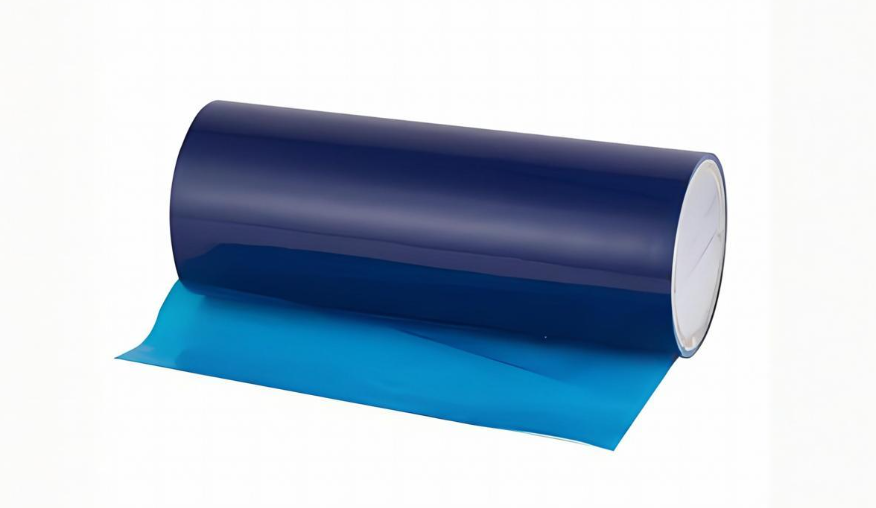

- PET Double-Sided Tape

PET double-sided tape uses PET (polyethylene terephthalate) film as the substrate. Known for its high strength, temperature resistance, and excellent electrical insulation properties, PET double-sided tape is commonly used in high-performance applications, especially in electronics and electrical industries.

Advantages:

- High strength and temperature resistance, suitable for electronics and electrical applications

- Excellent electrical insulation properties

- High stability and UV resistance

Applications:

- Component fixation in electronic and electrical products

- High-temperature applications

- Circuit board bonding and protection

- Acrylic Foam Double-Sided Tape

Acrylic foam double-sided tape uses thick foam material combined with acrylic adhesive. This type of tape offers strong adhesion and excellent durability, making it ideal for outdoor and high-performance applications. It has outstanding weather resistance, UV stability, and chemical resistance, making it ideal for extreme environments.

Advantages:

- Strong adhesive force, suitable for heavy-duty bonding

- Excellent weather resistance, UV stability, and chemical resistance

- Excellent shock absorption and vibration damping properties

Applications:

- Outdoor signage mounting

- Fixing construction materials

- High-strength automotive parts bonding

- How to Choose the Right Double-Sided Tape

When selecting the right double-sided tape, several key factors should be considered:

- Application Scenario: Choose the tape type based on the environmental conditions, such as temperature, humidity, and UV exposure. For outdoor applications, tapes with good weather resistance and UV protection, like acrylic foam double-sided tape, are preferred.

- Substrate Material: The material to be bonded also influences the choice of tape. Different tapes work better with specific surfaces, such as metal, plastic, or glass. The adhesive type must match the surface material for optimal bonding.

- Temperature and Humidity Resistance: If the application is in a high-temperature or humid environment, it is essential to select a tape with good heat resistance and moisture tolerance, such as PET or acrylic foam double-sided tapes.

- Adhesive Strength and Durability: Depending on the requirements of the bond, it is essential to choose the tape with the appropriate level of adhesion. For heavy-duty applications, tapes with high adhesive strength, like acrylic foam double-sided tape, are more suitable.

- Conclusion

Industrial double-sided tape is a versatile and widely used adhesive material in various industries. With advancements in technology, different types of double-sided tape have been developed to meet the specific needs of different applications. From nonwoven fabric, foam, and PET to acrylic foam, each type of tape has unique properties. By understanding the basic concepts and different types, users can make better choices based on their specific needs, ensuring that the tape will perform well and provide long-lasting adhesion in their applications.