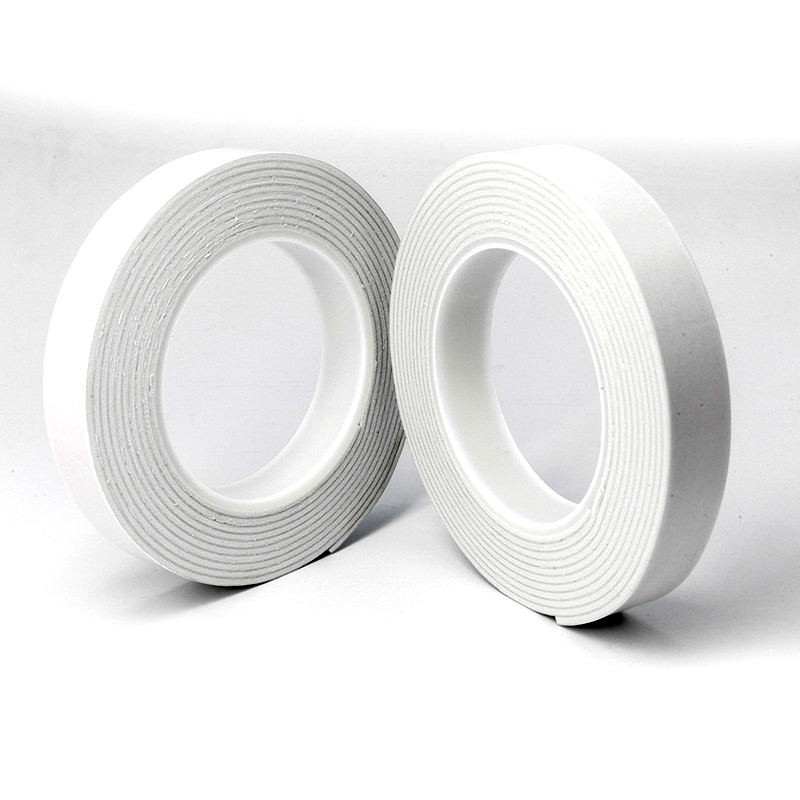

- Overview of Foam Double-Sided Tape

Foam double-sided tape is a type of adhesive tape made from foam materials (such as polyurethane foam, polyethylene foam, etc.) as the base material, with adhesive applied to both sides. Foam materials, known for their excellent elasticity and flexibility, make foam double-sided tape widely used in applications requiring sealing, cushioning, and vibration reduction. Typical features of foam double-sided tape include outstanding impact resistance, excellent temperature resistance, superior sealing capabilities, and exceptional shock-absorbing performance.

Compared to traditional paper or plastic-based tapes, foam double-sided tape offers not only strong adhesive power but also functions as a cushion and soundproofing barrier during the bonding process. This makes it especially suitable for industrial applications that require high levels of sealing and protection.

- Advantages of Foam Double-Sided Tape

- Excellent Sealing Performance

Foam materials have a closed-cell structure, which allows foam double-sided tape to form an effective seal between the surfaces it bonds, preventing the infiltration of air, moisture, dust, and other substances. Foam double-sided tape can fill the small gaps and irregularities on surfaces, ensuring the best possible sealing effect. This makes it ideal for environments where waterproofing, dust-proofing, and windproofing are necessary.

- Example Application: In the construction industry, foam double-sided tape is commonly used for sealing doors and windows, waterproofing walls, and sealing roof joints. It effectively prevents water, dust, and other external elements from entering the interior, maintaining dryness and cleanliness indoors.

- Outstanding Cushioning and Shock Absorption

Foam double-sided tape’s foam base not only provides flexibility but also effectively absorbs impact energy when subjected to external force, reducing the transmission of vibrations. This makes foam double-sided tape important in industries like packaging, shipping, and electronics assembly, where products need protection from damage due to vibrations or shocks. In applications where sensitive components need protection from external impacts, foam double-sided tape acts as an effective cushioning barrier.

- Example Application: In electronics packaging, foam double-sided tape is used to secure delicate components such as LCD screens and circuit boards. It effectively absorbs external impacts and reduces vibrations during transportation, helping to protect products from damage.

- Good Adaptability and Elasticity

Foam double-sided tape exhibits strong adaptability and elasticity, allowing it to bond to different surfaces, particularly when surfaces are uneven or irregular. The foam tape can deform according to the shape of the surface, providing a better fit. Whether on curved surfaces, rough surfaces, or in environments with large temperature variations, foam double-sided tape ensures long-lasting adhesion and sealing performance.

- Example Application: In the automotive industry, foam double-sided tape is used to bond window seals, providing a waterproof, soundproof, and sealed effect while adapting to the shape of the vehicle’s surface, reducing noise and improving comfort inside the car.

- High Temperature and Chemical Resistance

Foam double-sided tape is typically made with high-performance adhesives that offer good temperature resistance, maintaining stable adhesion even in high-temperature environments. Additionally, the foam material itself has some degree of chemical resistance, making it resistant to oils, acids, alkalis, and other chemicals. This makes foam double-sided tape suitable for use in harsh environments, such as engine compartments and industrial equipment, where stability is essential.

- Example Application: In the automotive industry, foam double-sided tape is used to fix and seal external car parts, such as components in the engine compartment and window seals, where it can withstand high temperatures and exposure to oil, ensuring the long-term reliability of the vehicle.

- Easy Installation and Use

Foam double-sided tape features a self-adhesive design, meaning it can be easily applied by simply placing the tape on the desired surface, removing the protective film, and directly bonding the surfaces without additional tools or complex procedures. Furthermore, foam double-sided tape is highly customizable and can be cut into various shapes and sizes to suit specific needs, making it convenient for flexible applications.

- Example Application: In furniture installation, foam double-sided tape can be used to secure soft materials, allowing for a quick and easy installation process without the need for complicated equipment, improving work efficiency.

- Applications of Foam Double-Sided Tape

- 1Automotive Industry

In the automotive manufacturing process, foam double-sided tape is widely used in window sealing, door waterproofing, interior part bonding, vibration reduction, and noise isolation. The cushioning and sealing properties of foam make it an essential material in the automotive industry.

- Typical Applications: Window seals, interior trim bonding, exterior trim installation, engine compartment sealing, and noise reduction.

- Electronics and Electrical Industry

Foam double-sided tape plays an important role in the electronics industry, providing cushioning and vibration protection. It is often used for packaging and protecting electronic components, especially those sensitive to external shocks and vibrations. Additionally, foam double-sided tape has good electrical insulation properties, making it suitable for use in electrical devices.

- Typical Applications: Packaging and securing electronic products, sensor installation, battery module protection, and vibration reduction for display screens.

- Construction and Home Improvement

In the construction and home improvement industry, foam double-sided tape is used for door and window sealing, wall soundproofing, and flooring installation. Its excellent sealing properties and shock resistance make it especially useful for applications requiring waterproofing, soundproofing, insulation, and vibration reduction.

- Typical Applications: Door and window seals, wall decoration and soundproofing, vibration-damping between floors and walls.

- Packaging and Logistics Industry

In the packaging and logistics industry, foam double-sided tape is used to protect fragile items and prevent damage during transportation. It not only helps secure items in place, preventing them from sliding or colliding but also absorbs external shock, reducing the risk of damage during transit.

- Typical Applications: Packaging fragile items, shock protection for transportation equipment, securing tools and electronic products.

- Conclusion

Foam double-sided tape offers a range of significant advantages, including its excellent sealing properties, shock absorption, and cushioning capabilities. Its strong adaptability, temperature and chemical resistance, and ease of use make it an indispensable material in many industries, such as automotive, electronics, construction, and packaging. Foam double-sided tape not only provides strong adhesion but also plays an essential role in reducing noise, absorbing vibrations, and protecting against external damage. Understanding the advantages and applications of foam double-sided tape can help users select the right tape for their specific needs, enhancing work efficiency, ensuring product quality, and reducing potential risks in both environmental and transportation conditions.