- Overview of PET Double-Sided Tape

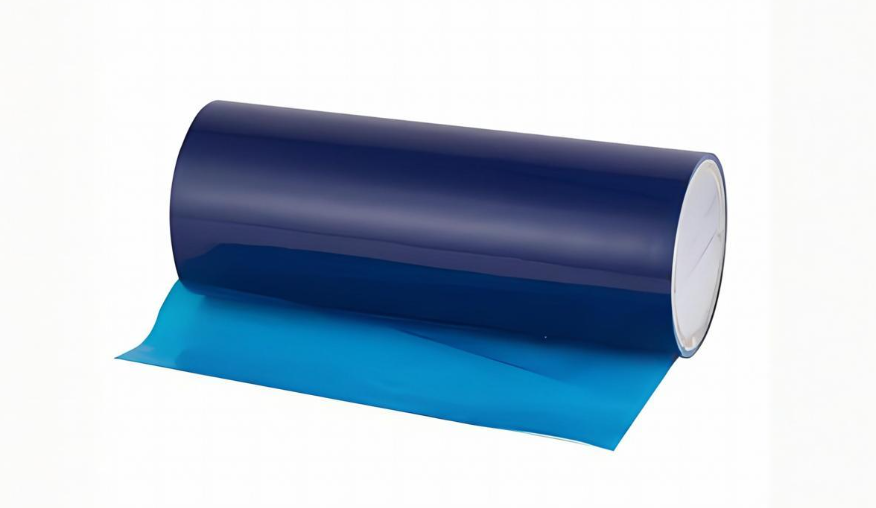

PET double-sided tape (Polyester double-sided tape) is a type of adhesive tape that uses a polyester film as its base material. PET (Polyethylene Terephthalate) is a high-strength material known for its excellent heat resistance, mechanical properties, and chemical stability. As a result, PET double-sided tape offers several advantages that traditional double-sided tapes cannot match, such as stronger adhesion, higher temperature tolerance, and better weather resistance. These properties make PET double-sided tape widely used in many high-demand industrial applications.

Key features of PET double-sided tape include:

- High-Temperature Resistance: PET double-sided tape is known for its excellent heat resistance, capable of withstanding high temperatures over extended periods, making it suitable for high-temperature processes.

- Strong Adhesion: PET double-sided tape uses high-performance pressure-sensitive adhesives, providing strong bonding power and stable adhesion on various surfaces.

- Excellent Weather Resistance: The stability of the PET base material ensures that the tape performs consistently in different environments, resisting UV radiation, moisture, and aging.

- High Tear Resistance: The PET film’s tear-resistant properties make the tape more durable and less likely to tear during use.

- Key Advantages of PET Double-Sided Tape

- Excellent High-Temperature Resistance

PET double-sided tape offers exceptional heat resistance, typically capable of withstanding temperatures around 150°C. Some specialized versions can endure even higher temperatures, making them ideal for high-temperature environments or processes. In industries such as electronics manufacturing, automotive production, and home appliances, PET double-sided tape can securely bond different materials without degrading or losing adhesion under high temperatures.

- Example Applications: In electronics manufacturing, PET double-sided tape is used to secure components on circuit boards or fix flexible circuits. During high-temperature soldering processes, PET tape retains its adhesive strength, ensuring the safety and stability of electronic components.

- Strong Adhesion and Long-Term Stability

PET double-sided tape utilizes high-performance pressure-sensitive adhesives, making it extremely strong and able to provide lasting bonding strength on a variety of surfaces. Its adhesion remains stable over time, even when exposed to changing environments, making it ideal for long-term bonding applications.

- Example Applications: In the automotive industry, PET double-sided tape is widely used for attaching exterior trim and parts to the vehicle body. Thanks to its strong adhesive properties, it ensures the stability of the vehicle’s appearance, preventing parts from detaching or loosening over time.

- Excellent Weather and UV Resistance

Thanks to the chemical stability of the PET base material, PET double-sided tape has excellent weather and UV resistance. In outdoor applications or environments exposed to strong sunlight, PET tape maintains its performance and does not degrade easily over time. This makes it highly suitable for outdoor equipment and installations that require long-term exposure to sunlight or harsh weather conditions.

- Example Applications: In the construction industry, PET double-sided tape is often used for sealing windows and attaching door frames, as these components are exposed to sunlight and environmental elements. The tape’s ability to resist UV radiation and environmental changes ensures a long-lasting, effective bond.

- High Tear Resistance and Mechanical Strength

PET double-sided tape has high mechanical strength and is resistant to tearing, making it more durable than traditional paper-based or plastic-based double-sided tapes. It can withstand substantial pull and tear forces, providing reliable performance in high-stress environments. PET tape ensures long-term adhesion, even in challenging conditions, preventing failure due to tears or breaks in the tape.

- Example Applications: In automotive manufacturing, PET double-sided tape is used to secure interior and exterior parts, particularly in areas where the parts may be subject to vibration or friction. The tape’s durability ensures that it will maintain its bond over time, even under challenging conditions.

- Applications of PET Double-Sided Tape

- Electronics Industry

PET double-sided tape is widely used in the electronics industry, especially for circuit board assembly, screen bonding, and flexible circuit fixing. With its excellent heat resistance and strong adhesion, PET double-sided tape offers robust support in the manufacturing and repair of electronic products. It can securely bond different components together and maintain its performance even in high-temperature environments.

- Example Applications: It is used for bonding components to LED display boards, securing LCD screens to substrates, or fixing batteries and other electronic components in place.

- Automotive Industry

In the automotive industry, PET double-sided tape is primarily used for body trim, part bonding, and sealing. Its strong adhesive properties and tear resistance make it an ideal choice for bonding parts that are exposed to high temperatures, moisture, and UV radiation, ensuring long-lasting performance and stability.

- Example Applications: PET double-sided tape is used for attaching external trim pieces, securing window seals, and installing internal components like dashboards. Its strong adhesion ensures that the parts stay in place over time, even under extreme conditions.

- Construction and Interior Design

In the construction industry, PET double-sided tape is used for window sealing, dust prevention, insulation, and other applications. During interior design projects, PET tape is used to fix carpets, wallpapers, and decorative trims, particularly in areas where temperature, moisture, and strong adhesion are critical.

- Example Applications: PET double-sided tape is used for sealing window frames and walls, ensuring a tight fit and preventing air or moisture infiltration.

- Packaging Industry

PET double-sided tape is widely used in the packaging industry for securing packaging materials, affixing labels, and meeting special packaging requirements. Its strong adhesion and durability ensure that items remain securely fixed during transit, reducing the risk of damage.

- Example Applications: It is used for securing electronic products during shipping, fixing precision instruments for transportation, or sealing high-end packaging.

- Conclusion

PET double-sided tape is an ideal adhesive solution for a wide range of high-performance applications. Its excellent heat resistance, strong adhesion, superior weather resistance, and tear strength make it the preferred choice in industries like electronics, automotive, construction, and packaging. Understanding the advantages and potential applications of PET double-sided tape helps users make the right selection, enhancing operational efficiency, product quality, and long-term reliability. By choosing PET tape, businesses can ensure strong, durable bonds that perform well even in challenging conditions.