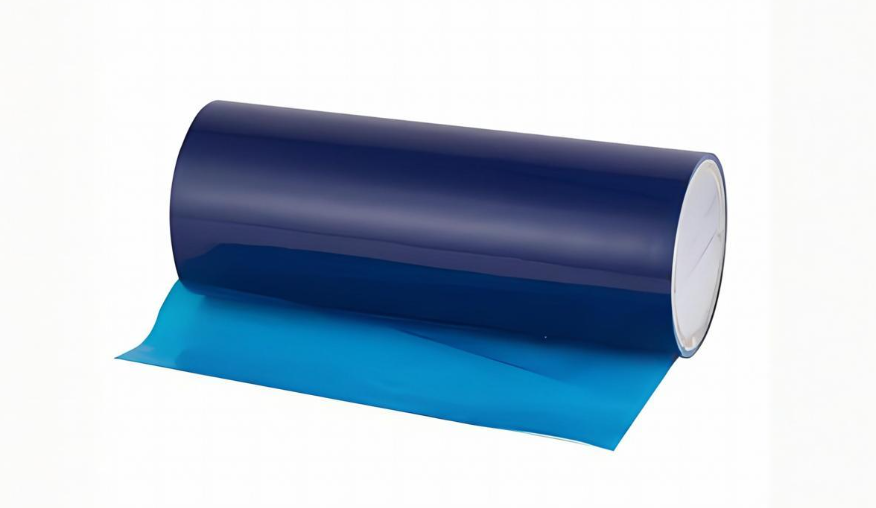

Surface protective films are widely used in various fields, such as home renovation, industrial production, and electronics, as an effective material to prevent surface damage, contamination, and wear. However, protective films can be affected by external factors and usage conditions. Without proper cleaning and maintenance, their lifespan can be significantly shortened. To ensure that protective films maintain their maximum protective effect and last longer, here are some common cleaning and maintenance tips.

-

Basic Principles for Cleaning Protective Films

-

Avoid Harsh Chemical Cleaners

When cleaning protective films, it’s important to avoid using harsh chemicals, such as ammonia, alcohol, benzene, or other corrosive substances. These chemicals can damage the film’s adhesive properties, causing it to yellow or become brittle, thus reducing its protective effectiveness. It is recommended to use neutral cleaners or mild detergents for cleaning, ensuring that the film’s performance remains unaffected.

-

Use Soft Cloths or Sponges

When cleaning protective films, avoid using rough cloths, brushes, or abrasive tools like steel wool. These materials can scratch the surface of the protective film, damaging its smoothness and transparency, which affects its protective function. It’s best to use soft cloths or sponges to wipe the surface, minimizing physical damage to the film.

-

Gently Wipe, Avoid Over-Rubbing

When cleaning protective films, use gentle wiping motions and avoid applying too much force. Excessive rubbing can damage the film surface and reduce the adhesive strength between the film and the protected surface, weakening the protective effect. Ensure even pressure when wiping to keep the film clean without causing damage.

-

How to Remove Stains and Grease

-

Removing General Stains

For general stains, such as dust, fingerprints, or light dirt, you can wipe the surface with a damp cloth. First, moisten the cloth with water or a mild detergent, and then gently wipe the film surface to remove the stain. If the stain is more stubborn, you can add a small amount of mild detergent to the water, but be careful not to use too much detergent, as it could leave residue on the film surface.

-

Removing Grease Stains

Grease stains are common on protective films, especially in kitchens, workshops, or industrial environments. To remove grease, you can gently wipe the surface with a mixture of warm water and neutral cleaner, or use a soft cloth dampened with a small amount of alcohol. Alcohol helps dissolve grease but should be used sparingly to avoid excessive exposure to the film, as it could damage the material.

-

Avoid Using Sharp Tools

When cleaning stubborn stains, avoid using sharp tools like blades or pointed brushes to scrape them off. Sharp objects can damage the surface of the protective film, leading to tears or loss of adhesion. If stains are difficult to remove, consider using specialized cleaning products designed for films. These products are specifically formulated to clean the film effectively without causing damage.

-

Regular Inspection and Maintenance

-

Regularly Check the Integrity of the Protective Film

Over time, protective films can be affected by external factors, leading to wear, bubbles, or peeling. Regularly inspecting the integrity of the film allows you to spot any issues early and prevent larger areas of damage. This is particularly important in environments with high temperatures, humidity, or frequent friction. If you notice any signs of aging, cracking, or peeling, it’s important to replace the film promptly to maintain optimal protection.

-

Avoid Exposure to High Temperatures and Direct Light

High temperatures and direct sunlight can accelerate the aging process of the protective film, causing its adhesive strength to decrease, discoloration, or brittleness. To extend the lifespan of the film, avoid exposing it to excessive heat, bright sunlight, or humid environments. If the film must be exposed to these conditions, consider using UV-resistant films or other materials with enhanced light resistance to slow down the aging process.

-

Keep the Film Surface Dry

Keeping the surface of the protective film dry is essential for extending its lifespan. Humid environments can reduce the film’s adhesive properties and may lead to mold growth, especially in areas with high moisture or during damp weather. Always ensure the surface of the film is kept clean and dry, and avoid prolonged exposure to damp environments. If moisture does accumulate, wipe the film dry promptly to prevent damage.

-

Proper Storage of Protective Films

-

Choosing the Right Storage Environment

When not in use, protective films should be stored in a dry, cool, and well-ventilated area, away from high temperatures, humidity, or direct sunlight. High temperatures and humidity can accelerate aging, while direct sunlight can cause the film to yellow or lose its adhesive properties. The ideal storage environment should maintain a temperature between 20-25°C (68-77°F) and relative humidity below 50%.

-

Avoid Contact with Sharp Objects

When storing protective films, ensure they are not in contact with sharp objects that could scratch or tear the surface. It is best to store the film rolled up rather than folded. Rolling the film helps avoid indentations or deformation of the surface, keeping it intact.

-

Check the Expiration Date

Every type of protective film has a certain shelf life. Expired films may lose their adhesive strength and effectiveness. Regularly check the production date of the protective film and avoid using films that are past their expiration date. To ensure optimal performance, it’s best to use the film within its shelf life.

-

Conclusion

With proper cleaning and maintenance, the lifespan of surface protective films can be significantly extended, ensuring they continue to provide excellent protection in home renovation, industrial production, and other applications. Avoiding harsh chemical cleaners, regularly checking the film’s integrity, keeping the surface dry and clean, and storing the film properly are all key factors in maintaining its performance over time. By following these simple and effective maintenance practices, you can maximize the performance of protective films, reducing unnecessary wear and replacement costs.

Read our related blog – Types and Applications of Industrial Adhesive Tapes. For regular updates, follow us on LinkedIn.