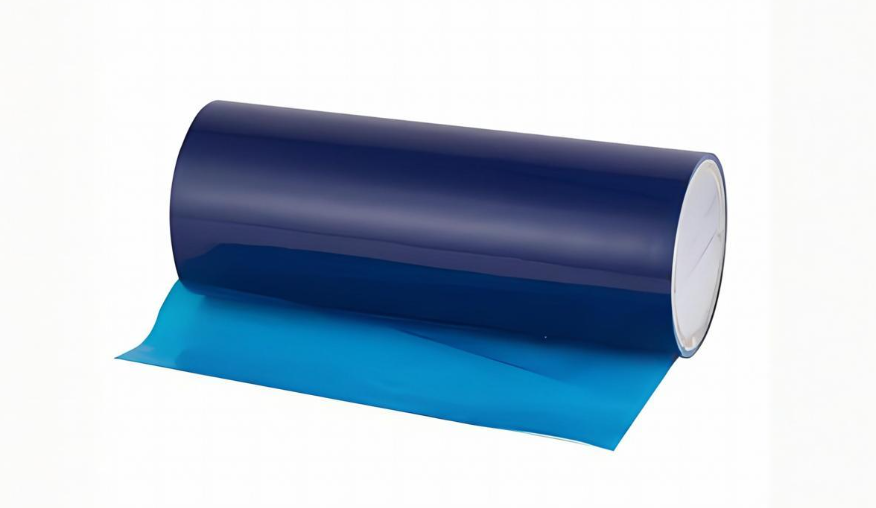

As the demand for surface protection continues to increase, surface protective films have become an efficient and convenient material widely used in various fields such as home renovation, industrial manufacturing, and logistics. Whether it’s protecting floors and walls during home renovation or safeguarding equipment and products in industrial production, surface protective films effectively prevent scratches, contamination, corrosion, and other issues caused by external factors. This article will introduce the applications of surface protective films in different scenarios and explore their perfect solutions in both home renovation and industrial applications.

-

Applications in Home Renovation

In home renovation, the main function of surface protective films is to protect furniture, floors, walls, and other surfaces from damage and contamination. Common application scenarios include:

-

Floor Protection

During home renovation, especially during painting, tiling, or furniture installation, floors are highly vulnerable to damage. Using surface protective films such as PE films and PVC films can effectively protect floors from paint, dust, dirt, and scratches. These films are typically highly adhesive and easy to peel off, leaving no adhesive residue after removal.

-

Furniture Surface Protection

Furniture surfaces are easily scratched or stained during renovation and transportation, particularly on high-gloss or wooden surfaces. In such scenarios, transparent PE or PET films can be used to protect the furniture. These films not only prevent scratches, dust, and stains but also maintain the furniture’s gloss and cleanliness.

-

Wall Protection

During wall painting, wallpaper installation, or repairs, walls are often splattered with paint or dust. Using surface protective films, such as waterproof PVC films or adhesive-free films, can effectively prevent the wall from becoming dirty with stains, paint splashes, and other materials. These films have good breathability and not only protect the wall but also avoid bubbles or uneven surfaces.

-

Window Protection

Windows are prone to contamination from paint, dust, glue, and other substances during renovation. Window protective films (such as window protection films) can effectively prevent external materials from sticking to the glass and are easy to remove afterward. These protective films are usually transparent and have excellent UV resistance and high-temperature resistance, making them suitable for various construction environments.

-

Applications in Industrial Settings

In addition to home renovation, surface protective films are also widely used in industrial fields. In manufacturing, transportation, and storage, surface protective films not only protect product surfaces from damage but also enhance product quality and value.

-

Electronics Manufacturing and Transportation

In the manufacturing of electronic products, such as smartphones, tablets, and televisions, surface protective films are widely used to protect screens, casings, and other components. PET films, PU films, and other high-performance films with excellent transparency and wear resistance can effectively prevent products from being scratched or leaving fingerprints during production, packaging, and transportation. Particularly in high-end electronic products, surface protective films also protect devices from static, dust, and other external contaminants.

-

Automotive Manufacturing and Repair

In the automotive production and repair process, the use of protective films is crucial. During car painting, protective films can prevent paint from scratching or contaminating external parts. Especially in areas such as automotive glass, dashboards, and seats, surface protective film can prevent contamination, scratches, and stains from affecting the appearance and quality of the vehicle. Common protective films in the automotive industry include transparent PET films and PU films, which offer strong weather resistance and UV protection, ensuring long-term effective protection in outdoor environments.

-

Construction and Renovation

In construction and renovation, surface protective film are widely applied to protect surfaces such as glass, metal panels, marble, and tiles. Especially during the transportation and installation of building glass and metal panels, protective films can prevent scratches, cracks, or contamination of the surfaces. Additionally, many protective films can minimize wear and tear on surface coatings during construction, ensuring the materials maintain their intended performance and appearance.

-

Solar Photovoltaic Industry

In the solar photovoltaic industry, protective films are essential for the production and transportation of solar panels. Solar panels need to be protected from scratches or contamination during manufacturing, and protective films can effectively shield the photovoltaic surface from damage. PET films and nanocoating films are commonly used to protect solar panels due to their excellent high-temperature resistance and ability to prevent external dust, dirt, and mechanical damage.

-

Advantages of Surface Protective Films

Surface protective films have become the ideal choice for both home renovation and industrial applications due to their numerous advantages. The key benefits include:

-

Effective Protection

Surface protective films have excellent abrasion resistance, scratch resistance, and contamination resistance, effectively preventing damage from external elements. Whether during renovation or in transportation and storage stages, these films minimize the risk of surface damage.

-

Ease of Use

Protective films are typically designed to be easy to apply and remove without leaving adhesive residue. Even after prolonged use, the films maintain their adhesive properties and will not tear or peel off. Most protective films are transparent, allowing for easy visibility of the surface being protected.

-

Environmentally Friendly

With increasing environmental regulations, many surface protective films are made from eco-friendly materials such as non-toxic PE films or biodegradable films, meeting modern green standards. Using these environmentally friendly materials not only protects surfaces but also reduces environmental impact.

-

Cost-Effective

Compared to traditional surface protection methods (such as fabric covers or plastic sheets), surface protective film offer a higher cost-performance ratio. They are not only more affordable but also provide long-lasting protection, reducing material waste and project delays, thus improving work efficiency.

-

Conclusion

Surface protective film, as a highly functional material, are widely applied in various fields, including home renovation and industrial manufacturing. Whether protecting floors, furniture, or walls, or safeguarding electronic products, automotive parts, and construction materials, surface protective film provide efficient protection and minimize surface damage and contamination, enhancing the quality and value of products. With continuous advances in materials science, future protective films will become more environmentally friendly, intelligent, and multifunctional, offering even more perfect protection solutions for various industries.

Read our related blog – Types and Applications of Industrial Adhesive Tapes. For regular updates, follow us on LinkedIn.