With the continuous advancement of industrialization and the improvement of living standards, the application of surface protective films has become increasingly widespread in various industries. Traditional protective film materials, such as polyethylene (PE) films and polyvinyl chloride (PVC) films, are no longer able to meet the high-performance protection needs of modern applications. To address more complex protection requirements, many new high-performance protective film materials have emerged. This article will introduce some of these new high-performance protective film materials and their development trends, as well as explore their application prospects in different industries.

-

New High-Performance Protective Film Materials

-

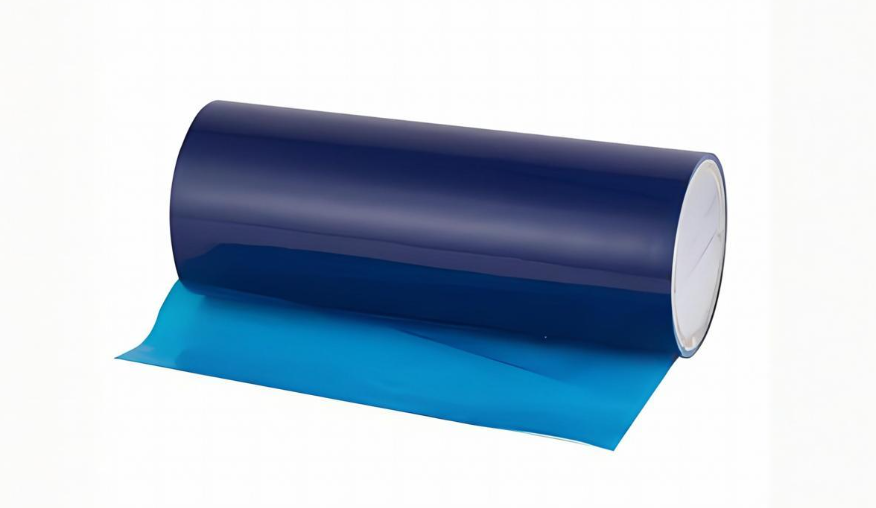

Polyester Films (PET Films)

Polyester films (PET films) are high-performance polymer materials with excellent temperature resistance, UV protection, mechanical strength, and chemical resistance. Compared to traditional PE films, PET films offer higher tensile strength and better high-temperature resistance, making them suitable for a wider range of environments. For example, PET films are widely used in the electronics, photovoltaics, and home appliances industries for surface protection, effectively preventing scratches and contamination.

-

Polyurethane Films (PU Films)

Polyurethane films (PU films) have become the preferred material for many high-performance protective films due to their outstanding elasticity, wear resistance, and weather resistance. Compared to traditional films, PU films offer better stretchability and durability, making them suitable for harsher environments. They are commonly used in surface protection for electronic products, automotive coatings, and furniture, especially in applications requiring high transparency and strength.

-

Adhesive-Free Protective Films

Adhesive-free protective films are a new type of environmentally friendly protective film that adheres to surfaces using special physical methods instead of traditional adhesives. These films offer high transparency and strong tear resistance, and they do not leave adhesive residue after use, making them ideal for areas requiring high cleanliness, such as glass, metal, and high-end electronic device protection.

-

Nanocoating Protective Films

Nanocoating protective films are thin films produced using nanotechnology, providing multiple functions such as water resistance, stain resistance, antibacterial properties, and UV protection. These materials not only offer effective surface protection but also enhance the self-cleaning properties of the film through the molecular structure at the nanoscale. Nanocoating protective films are widely used in high-end mobile phones, automotive glass, and building glass, with significant market potential.

-

Biodegradable Protective Films

With the increasing emphasis on environmental protection, biodegradable materials have begun to enter the field of protective films. Biodegradable protective films typically use plant-based materials, such as corn starch and polylactic acid (PLA), which can naturally decompose after use, reducing environmental pollution. These films are mainly used for single-use packaging and surface protection, offering eco-friendly, non-polluting advantages.

-

Application Areas of New High-Performance Protective Film Materials

-

Electronics

As electronic products such as smartphones, tablets, and laptops become more widespread, the use of protective films in these devices is growing. New high-performance protective films, such as PET films, PU films, and nanocoating films, effectively prevent scratches, pollution, and fingerprints on electronic devices. These films also provide UV protection, antibacterial properties, and other functions, extending the lifespan of electronic products.

-

Automotive Industry

The demand for protective films in the automotive manufacturing and repair industries is also increasing. Especially during automotive painting, PU films and PET films are widely used for surface protection to prevent paint peeling, scratches, and other issues. In automotive glass, dashboards, and seats, nanocoating protective films are increasingly used to improve water resistance, stain resistance, and UV protection.

-

Construction and Interior Design

In the construction and interior design industries, especially during the transportation and installation of high-end materials such as marble, glass, and metal panels, the use of new high-performance protective films is critical. PET films and PU films can effectively protect surfaces from scratches, stains, and damage from the external environment. These materials play a crucial role in protecting building glass, metal facades, and tiles.

-

Photovoltaic and Solar Energy

The photovoltaic industry also has a growing demand for protective films, especially during the production and transportation of solar panels. PET films and nanocoating films are widely used in solar panel protective films due to their excellent light transmission and weather resistance. As the photovoltaic industry continues to grow, the demand for high-performance protective films will continue to increase.

-

Development Trends of New High-Performance Protective Film Materials

-

Environmental and Sustainable Development

Environmental protection is a key development trend in material science and manufacturing. With stricter environmental regulations and growing consumer awareness of sustainability, biodegradable protective film materials will become an important direction for future development. It is expected that the protective film industry will see the emergence of more environmentally friendly materials that are degradable, non-toxic, and non-harmful.

-

Diversification of Functions

The future of protective films will go beyond traditional functions such as scratch resistance, stain resistance, and water resistance. With technological advancements, new protective film materials will be equipped with additional smart functions such as self-repair, antibacterial properties, and UV protection. The application of nanotechnology and smart materials will make protective films more multifunctional, addressing increasingly complex protection needs.

-

Enhanced Performance

In the future, the performance of protective films will be further improved, especially in terms of high-temperature resistance, chemical resistance, UV protection, and corrosion resistance. With advancements in material science, new protective films will exhibit greater durability and adaptability, allowing them to be used in harsher environments.

-

Smart Development

As smart technologies advance, the development of smart protective films is also becoming a trend. For example, protective films equipped with smart sensing technology could detect temperature, humidity, or external impacts and automatically adjust the hardness or permeability of the film. These smart protective films will find widespread applications in high-tech fields such as healthcare, aerospace, and electronics.

-

Conclusion

With the progress of technology and the changing market demands, new high-performance protective film materials continue to innovate and develop. The emergence of materials such as polyester films, polyurethane films, adhesive-free protective films, nanocoating films, and biodegradable films has greatly expanded the range of protective film applications and enhanced their functionality and environmental friendliness. In the future, with stricter environmental regulations, more diverse functional requirements, and the development of smart technologies, protective film materials will evolve toward higher performance, greater environmental sustainability, and enhanced intelligence, providing more efficient surface protection solutions for various industries.

Read our related blog – Types and Applications of Industrial Adhesive Tapes. For regular updates, follow us on LinkedIn.