Introduction

Industrial adhesive tape plays a vital role in various industries, but improper use or storage can affect its performance and effectiveness. Understanding how to properly store and use industrial adhesive tape is key to ensuring its optimal results. This article will provide practical storage and usage tips to help readers maximize the advantages of industrial adhesive tape.

1. Storage Considerations for Tape

Proper storage methods can significantly extend the lifespan of adhesive tape. Here are some important considerations when storing tape:

- Temperature and Humidity Control

Tape should be stored in a dry, cool environment, avoiding high temperatures and humidity. Extreme temperatures and humidity can affect the adhesive performance, causing it to lose stickiness or deform. Ideal storage temperatures typically range from 15°C to 25°C, and humidity should be controlled between 40% and 60%. - Avoid Direct Sunlight

Tape should be kept out of direct sunlight for extended periods, as UV rays can reduce adhesive strength. When storing, choose a dark storage room or use opaque containers to shield the tape from light. - Keep Away from Chemicals

Tape should be kept away from chemical substances, such as solvents and acids, which can degrade its performance. Ensure that the tape is stored at a distance from potentially corrosive materials. - Proper Stacking

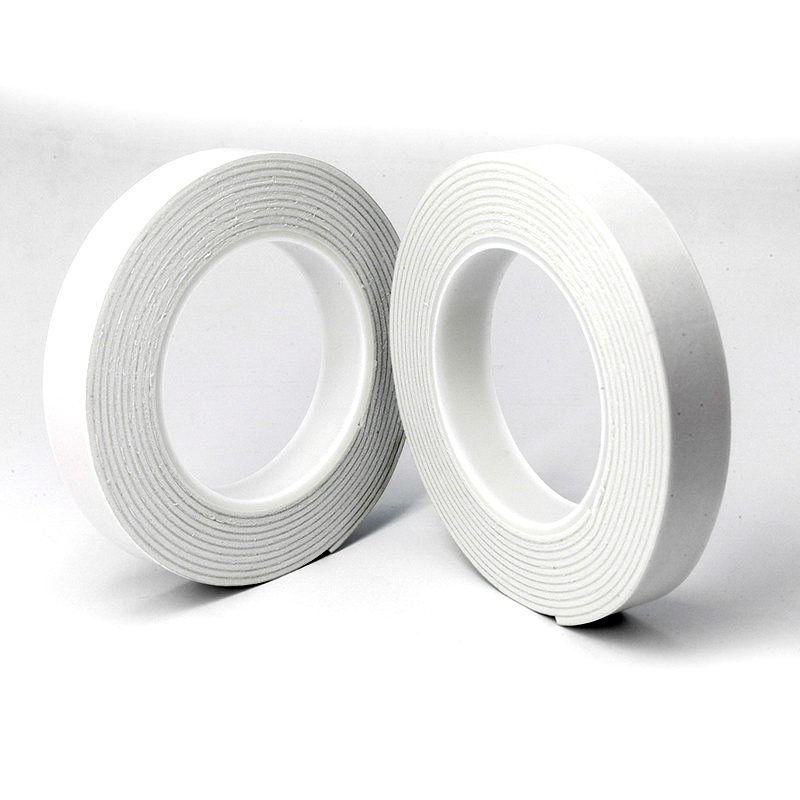

Tape rolls should be stored flat or upright, avoiding heavy objects on top to prevent deformation or adhesive flow. When storing, avoid direct contact with the floor to prevent dust and dirt from contaminating the tape.

2. Usage Tips for Tape

In addition to storage, some usage tips can enhance the effectiveness of adhesive tape:

- Select Appropriate Surfaces

Before using tape, ensure that the bonding surface is clean, dry, and free of grease. Clean the surface with a cleaner or alcohol to remove any impurities that may affect adhesion. - Apply Even Pressure

When applying tape, exert uniform pressure to ensure good contact between the tape and surface. Use a roller or your palm to gently press down, ensuring the tape adheres well. - Follow Usage Timing

When peeling off the tape, adhere to the manufacturer’s recommended timing. If used in high-temperature or humid environments, it may be necessary to shorten the waiting time after application to achieve optimal adhesion. - Avoid Overstretching

When using tape, avoid overstretching it. Overstretching can cause the tape to lose its adhesive properties or tear during use, affecting its overall performance. - Regularly Inspect

During use, regularly check the adhesive condition of the tape. If you notice loosening or peeling, promptly reapply it to maintain continuous adhesion.

3. Effective Usage Cases for Tape

Understanding some practical cases can help readers better grasp how to effectively use industrial adhesive tape:

- Fixing Electronic Components

In the assembly of electronic products, double-sided tape can conveniently secure components to the circuit board. Ensure that the surface of the circuit board is clean beforehand to achieve the best adhesion. - Applications in Construction and Renovation

In construction and renovation, cloth tape can be used for temporarily securing materials, such as fixing drywall or wallpaper. When applying, be sure to apply even pressure immediately after sticking to ensure the stability of the materials. - Usage in Logistics Packaging

In the logistics industry, paper tape is often used for sealing boxes. When using, ensure that the paper tape fully covers the seams of the box to prevent items from shifting or falling during transport.

Conclusion

Proper storage and usage techniques are crucial for ensuring the optimal performance of industrial adhesive tape. By following storage considerations and applying usage tips, readers can fully leverage the advantages of tape in their work, enhancing efficiency and product quality. In upcoming articles, we will explore innovative applications of different types of tape, so stay tuned!