In modern warehouse and logistics management, safety is always a top priority. As warehouse operations scale up and logistics efficiency increases, the risk of accidents also rises. Effectively using identification and management tools to enhance the safety of warehouses and logistics centers has become a key focus for managers. Safety warning tape, with its efficiency, flexibility, and cost-effectiveness, has become an indispensable safety identification tool in the field of warehouse and logistics.

This article explores the features, applications, and critical role of safety warning tape in improving safety in warehouse and logistics operations, highlighting its practicality and necessity.

- Features of Safety Warning Tape

- Highly Visible Warning Effect

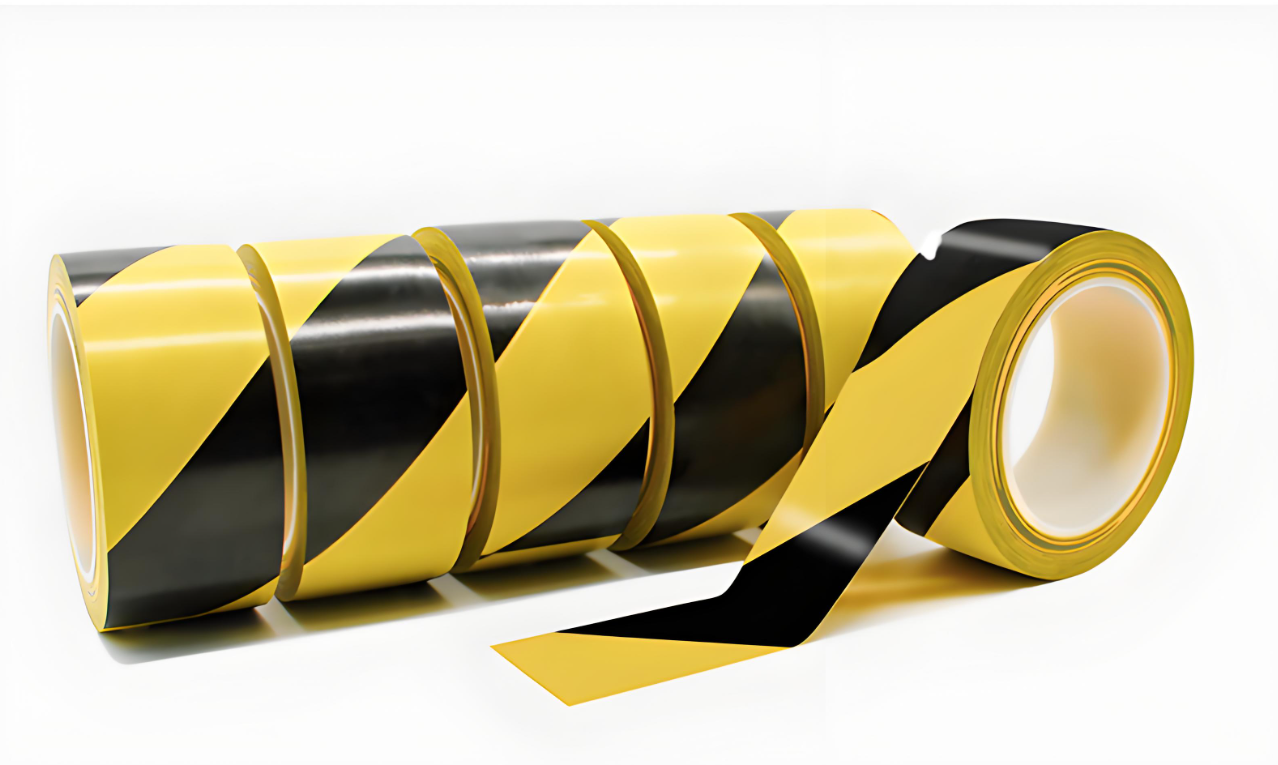

Safety warning tape typically uses high-contrast color combinations (e.g., yellow and black, red and white) and internationally recognized patterns, making it easy to draw attention. Even in dimly lit or busy warehouse environments, it effectively communicates clear warning messages. - Durability

Made of high-strength materials such as PVC or PET, safety warning tape is highly resistant to abrasion, tearing, and aging, ensuring long-term use in high-traffic areas or heavy machinery zones. - Versatility

Some warning tapes also feature anti-slip functionality, providing extra safety in wet floors, slopes, or elevated work areas. - Flexibility and Convenience

Easy to install and remove without the need for complex tools, safety warning tape can be repositioned as needed, making it ideal for the dynamic operations of warehouses and logistics centers. - Applications of Safety Warning Tape in Warehousing and Logistics

- Zoning and Path Guidance

Safety warning tape is widely used for zoning in warehouses, such as:- Separating storage and passage areas: It clearly demarcates areas for goods storage and pedestrian movement, reducing the risk of collisions between forklifts and workers.

- Marking hazardous material zones: Tapes applied to areas storing chemicals or hazardous materials serve as reminders for employees to exercise caution and follow specific safety procedures.

- Hazard Boundary Warnings

- Loading dock edges: Red and white warning tape applied along loading dock or elevated area edges clearly marks hazardous boundaries, preventing falls for personnel or equipment.

- Stair and ramp protection: Anti-slip warning tape on stairs or ramps reduces the risk of slips and falls due to wet or uneven surfaces.

- Shelf Marking and Safety Protection

- Tapes applied to shelf supports or edges enhance visibility, reducing the chance of forklifts or handling equipment colliding with shelf structures.

- On mobile shelving systems, tape markings indicate movement boundaries, keeping personnel safe from potential dangers posed by moving shelves.

- Emergency Path and Exit Identification

- Green warning tape is often used to mark emergency evacuation paths and exits on warehouse floors, ensuring employees can evacuate quickly and safely during emergencies.

- The Importance of Safety Warning Tape in Enhancing Warehouse and Logistics Safety

- Reducing Accident Risks

- Clear zoning and boundary markings help prevent forklift collisions, accidental entry into hazardous areas, and disorderly storage of goods.

- Anti-slip warning tape reduces slip accidents on wet floors, further ensuring worker safety.

- Improving Operational Efficiency

- Clear path guidance and zone identification minimize confusion in complex environments, streamlining logistics operations.

- For example, during peak loading and unloading operations, warning tape guides forklifts along designated routes, preventing congestion or collisions caused by overlapping pathways.

- Enhancing Management Standards

- Using warning tape to mark different zones reinforces visual management in warehouses, enabling employees to understand the purpose and safety requirements of each area clearly.

- Standardized application of warning tape also raises employee awareness and compliance with safety protocols.

- Supporting Emergency Response

- During emergencies (e.g., fires or earthquakes), clearly marked evacuation paths help employees quickly locate safe exits, reducing casualties.

- Warning tape in hazardous areas aids rescue teams in assessing the environment and formulating effective response plans.

- Cost Reduction

- Compared to complex safety protection equipment, safety warning tape is a cost-effective solution. Its ease of installation and replacement adapts to various scenarios, reducing long-term maintenance costs.

- Recommendations for Using Safety Warning Tape

- Select Appropriate Colors and Types

- Choose colors that comply with international standards based on specific applications. For example, yellow and black tape is used to warn of hazardous areas, while red and white tape marks prohibited zones or boundaries.

- Inspect and Replace Regularly

- Regularly check for wear and tear on the tape, replacing it when necessary to maintain clarity and effectiveness.

- Combine with Other Safety Tools

- Use warning tape alongside protective equipment like bollards or barriers for comprehensive safety coverage in high-risk areas.

- Employee Training and Standardized Management

- Ensure employees understand the purpose and significance of warning tape, emphasizing adherence to safety guidelines in daily operations.

Conclusion

Safety warning tape plays a critical role in warehousing and logistics, providing reliable support for zoning, path guidance, boundary protection, and emergency management. With its flexibility, cost-effectiveness, and efficiency, it effectively reduces accident risks and enhances operational efficiency and management standards. By properly applying safety warning tape, businesses can create safer, more organized working environments for their employees.