In modern factories and warehouses, floor marking tape has become an essential and efficient management tool, widely used for layout planning, material storage, personnel pathways, and marking hazardous areas. It not only enhances workplace safety and production efficiency but also helps businesses achieve more refined and standardized management practices. This article will explore in detail the role of floor marking tape in factories and warehouses, particularly its importance in safety management, space planning, and process optimization.

- Enhancing Workplace Safety

In factories and warehouses, workers often navigate through busy environments, which can lead to accidents such as collisions or slips if not properly managed. Floor marking tape helps clearly define safe areas, walkways, equipment zones, and hazardous areas, thus reducing the likelihood of accidents.

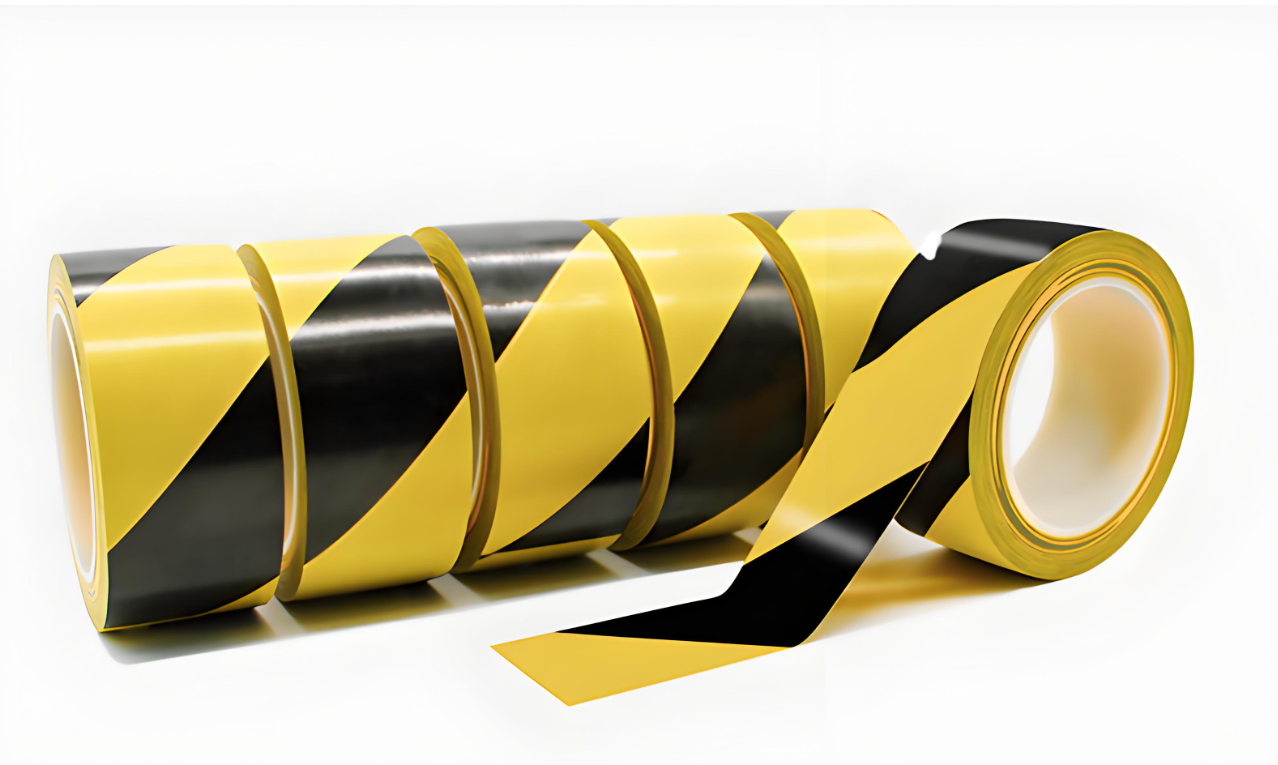

- Marking Hazardous Areas: Many production plants or storage areas pose potential hazards, such as high temperatures, high pressure, or chemical spills. Using conspicuous floor marking tape, these hazardous zones can be clearly identified, and workers can be warned to avoid them for safety. For example, chemical storage areas, electrical equipment zones, etc., are often marked with yellow, red, or other cautionary colors to alert personnel of potential dangers.

- Defining Walkways: In complex work environments, it’s essential to ensure workers can walk safely and efficiently. Floor marking tape is used to define designated walkways, helping to minimize collisions between workers and ensuring smooth movement. This is particularly important during emergencies when personnel need to evacuate quickly.

- Emergency Exit Signage: In emergency situations, clear signage is vital for ensuring workers can evacuate quickly. Floor marking tape is often used to indicate the direction of emergency exits, especially in large warehouses and production areas, playing a crucial role in guiding workers to safety.

- Standardizing Production Line Layouts

In factories and production plants, the optimization of the production line layout directly affects work efficiency. With proper floor marking, factories can effectively standardize material flow, production processes, and worker locations, ensuring smooth and efficient operation.

- Material Storage Zone Demarcation: In warehouses and production areas, floor marking tape can be used to define storage zones for different materials. Different colors of tape correspond to different types of materials or equipment, allowing workers to quickly locate the required items, thus avoiding wasted time and confusion.

- Optimizing Production Processes: By using floor markings, factories can clearly outline each stage of the production process, ensuring that workers follow the correct routes and procedures. This helps avoid disruptions and inefficiencies due to unclear processes. For instance, some production lines may use green tape to indicate “material flow zones” and yellow tape for “inspection areas,” helping workers distinguish between different tasks.

- Work Area and Task Zone Identification: Floor marking tape also helps clearly define each work area’s responsibilities. In high-precision operations, workers can use floor markings to identify their specific work zones, reducing errors caused by confusion over task locations.

- Improving Warehouse Management Efficiency

As the core area for storing and distributing materials, warehouse management directly impacts the efficiency of the entire supply chain. The use of floor marking tape in warehouses significantly improves inventory management and operational efficiency.

- Shelf and Item Location: In warehouses, floor marking tape is commonly used to mark the location of shelves, storage areas, and entry-exit pathways. Clear markings help employees quickly find the correct shelf or storage zone, enhancing the efficiency of inventory management and minimizing delays during picking.

- Item Classification and Organization: Different types of items can be classified and managed using floor marking tape. For example, red tape can be used to mark hazardous material storage areas, green tape for general goods, and blue tape for high-value items. This way, employees can quickly identify different types of items, speeding up inventory management and ensuring proper handling.

- Forklift Pathways and Traffic Routes: Warehouses typically have numerous forklifts and other transport equipment in use. Floor marking tape is used to clearly delineate forklift routes and material handling areas, ensuring safe distances between workers and vehicles and minimizing the risk of collisions.

- Promoting Continuous Improvement and Visual Management

Another important function of floor marking tape is to support continuous improvement and visual management in factories and warehouses. By providing clear and visible markings, businesses can more easily identify bottlenecks, problem areas, and potential safety hazards, allowing for targeted improvements.

- Kanban Management: Floor marking tape can be integrated with Kanban management to visualize key production metrics. For instance, different colors of tape can be used to represent production progress, quality control points, or production goals along the production line. This helps managers and workers quickly assess the current state of production and adjust schedules accordingly.

- Problem Feedback and Area Identification: By setting aside specific marked zones in factories and warehouses, businesses can easily identify areas with recurring issues and track improvement actions. For example, if a particular workstation frequently encounters quality problems, it can be highlighted using floor marking tape, serving as a reminder for investigation and improvement.

- Cost-Effectiveness and Easy Maintenance

Compared to traditional fixed signage or wall-mounted indicators, floor marking tape is cost-effective and easy to install and maintain. It can be quickly replaced or adjusted to accommodate changes in production layouts or warehouse management needs.

- Low Cost, High Efficiency: Floor marking tape is inexpensive and easy to install, making it a cost-effective solution compared to traditional signage systems. It allows businesses to clearly define work zones, optimize workflows, and improve safety without significant investment in infrastructure.

- Easy to Update and Adjust: As production lines or warehouse layouts change, floor marking tape can be easily updated or replaced to reflect new needs. This flexibility significantly improves a company’s ability to adapt to changing circumstances.

Conclusion

The use of floor marking tape in factories and warehouses not only enhances workplace safety but also standardizes production and inventory management processes, and promotes continuous improvement and efficient operation. By carefully planning and implementing floor markings, businesses can reduce the likelihood of accidents, improve production efficiency, streamline material flow, and better manage inventory, all while maintaining a safer, more organized environment. Floor marking tape is a simple, low-cost solution that can have a significant positive impact on operational efficiency and workplace safety in industrial settings.

Read our related blog – Types and Applications of Industrial Adhesive Tapes. For regular updates, follow us on LinkedIn.